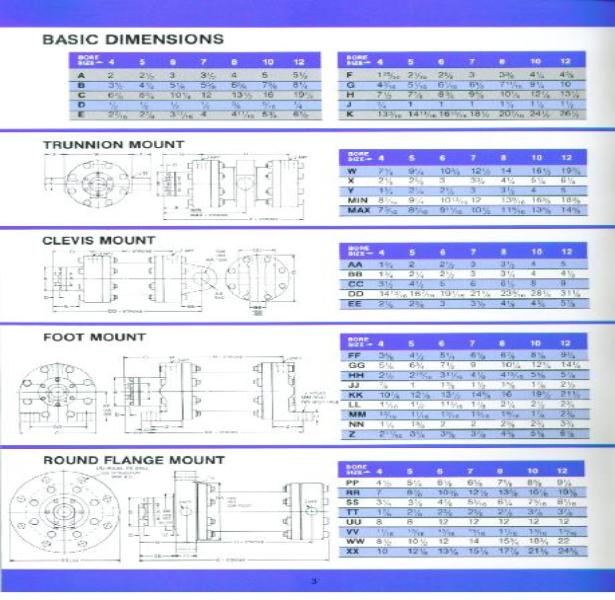

Basic Dimensions

Hydraulic Cylinders Basic Dimensions

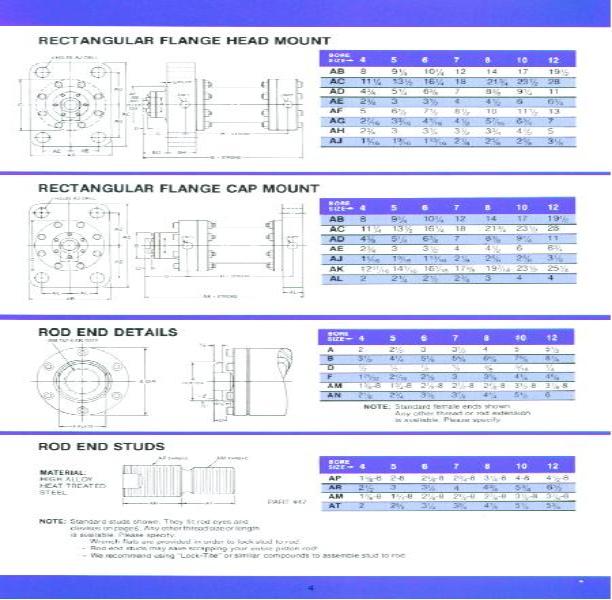

Hydraulic Cylinders Rectangular Flange Head Mount

Hydraulic Cylinders Mounting Accessories

Finally maintenance men have a high-pressure, heavy duty, mill type hydraulic cylinder specifically designed

to require less maintenance, longer life, less spares, and lower maintenance cost during the life of the

cylinder.

The time-tested, on-the-job proven axiom that "if a given hydraulic cylinder can be made longer, it will

perform better" has been the design guideline for the Hadady hydraulic cylinders. With a zero stroke, the rod

and tube cost from approximately 8 to 16% of the cylinder. With a stroke of 5 times the bore size, the rod and

tube cost approximately 25 to 55% of the whole cylinder. Therefore, in medium to long stroke units, it is

economical in the long run to have a higher original cost and protect the rod and tube from damage in

service.

Our bronze rod bearing length is one and one half times the rod diameter in cushioned units (part #26 on

diagram.) and two to two and one half times the rod diameter in non-cushioned units (part #29 on diagram).

Our pistons are from two-thirds to one times the bore size in length. No standard hydraulic cylinder design

can make this claim!

Our piston design incorporates a one piece steel piston (part #22 on diagram) with a split bronze center ring

(part #27 on diagram) and non-metallic piston wear rings (part #28 on diagram) on either side to provide the

ultimate in anti-scoring design. The piston is piloted both in front and back to the rod to assure absolute

concentricity. The steel tube is the most expensive component of the pneumatic cylinder and deserves the

extraordinary protection that the anti-score piston design provides. Easy replacement of the piston wearing

parts and seals is a built-in feature of the Hadady anti-score design. Utilization of the high-strength, self-

energizing, non-abrading urethane seals on the rod (part #36 on diagram) and piston (part #33 on diagram)

further enhances the life of this heavy duty hydraulic cylinder. Service inspection has actually shown that this

seal will improve the finish in the cylinder bore and on the rod surface.

The piston rod is the second most expensive component of many mill type cylinder configurations. Service

has proven that a high tensile base material with a hardened case and chrome plating provides the best

protection of this exposed sealing surface. The cap cushion spear is bronze clad for further protection and all

standard rods have a .001" thickness of chrome plating.

The rigidity of the long rod bearing supporting the rod also enhances the performance and life of the

urethane rod seal. The rods are also protected by a urethane wiper (part #37 on diagram). The rod seal is

located as far forward as possible to provide for as much lubrication in the rod bearing area as possible. All

of our rods are tapped with a female thread on the customer’s end. If the customer desires a male threaded

connection, an alloy high-tensile stud is provided to eliminate costly replacements of complete piston rods.

Other Hadady Hydraulic Cylinder Features

Generous chamfers on the rod, rod bearing cavity and tube allow easy, reliable assembly.

All the standard mounting styles utilize grade 8 high strength socket head cap screws and nuts.

All the heads and caps are made of fabricated or cast steel.

Mounting accessories - rod eye, rod clevis, clevis mounting bracket, and clevis pin - are steel.

Chrome plating of bores is optional. Please specify on your order.

Section VIII of the ASME Pressure Vessel Code has been used throughout as the design guide of the

Hadady mill cylinder.

We realize our standard cylinder is limited in bore size and rod selection. Receive a free quote for your

requirements in any size, pressure or mounting style incorporating the outstanding features of the Hadady

heavy duty hydraulic cylinder.

to require less maintenance, longer life, less spares, and lower maintenance cost during the life of the

cylinder.

The time-tested, on-the-job proven axiom that "if a given hydraulic cylinder can be made longer, it will

perform better" has been the design guideline for the Hadady hydraulic cylinders. With a zero stroke, the rod

and tube cost from approximately 8 to 16% of the cylinder. With a stroke of 5 times the bore size, the rod and

tube cost approximately 25 to 55% of the whole cylinder. Therefore, in medium to long stroke units, it is

economical in the long run to have a higher original cost and protect the rod and tube from damage in

service.

Our bronze rod bearing length is one and one half times the rod diameter in cushioned units (part #26 on

diagram.) and two to two and one half times the rod diameter in non-cushioned units (part #29 on diagram).

Our pistons are from two-thirds to one times the bore size in length. No standard hydraulic cylinder design

can make this claim!

Our piston design incorporates a one piece steel piston (part #22 on diagram) with a split bronze center ring

(part #27 on diagram) and non-metallic piston wear rings (part #28 on diagram) on either side to provide the

ultimate in anti-scoring design. The piston is piloted both in front and back to the rod to assure absolute

concentricity. The steel tube is the most expensive component of the pneumatic cylinder and deserves the

extraordinary protection that the anti-score piston design provides. Easy replacement of the piston wearing

parts and seals is a built-in feature of the Hadady anti-score design. Utilization of the high-strength, self-

energizing, non-abrading urethane seals on the rod (part #36 on diagram) and piston (part #33 on diagram)

further enhances the life of this heavy duty hydraulic cylinder. Service inspection has actually shown that this

seal will improve the finish in the cylinder bore and on the rod surface.

The piston rod is the second most expensive component of many mill type cylinder configurations. Service

has proven that a high tensile base material with a hardened case and chrome plating provides the best

protection of this exposed sealing surface. The cap cushion spear is bronze clad for further protection and all

standard rods have a .001" thickness of chrome plating.

The rigidity of the long rod bearing supporting the rod also enhances the performance and life of the

urethane rod seal. The rods are also protected by a urethane wiper (part #37 on diagram). The rod seal is

located as far forward as possible to provide for as much lubrication in the rod bearing area as possible. All

of our rods are tapped with a female thread on the customer’s end. If the customer desires a male threaded

connection, an alloy high-tensile stud is provided to eliminate costly replacements of complete piston rods.

Other Hadady Hydraulic Cylinder Features

Generous chamfers on the rod, rod bearing cavity and tube allow easy, reliable assembly.

All the standard mounting styles utilize grade 8 high strength socket head cap screws and nuts.

All the heads and caps are made of fabricated or cast steel.

Mounting accessories - rod eye, rod clevis, clevis mounting bracket, and clevis pin - are steel.

Chrome plating of bores is optional. Please specify on your order.

Section VIII of the ASME Pressure Vessel Code has been used throughout as the design guide of the

Hadady mill cylinder.

We realize our standard cylinder is limited in bore size and rod selection. Receive a free quote for your

requirements in any size, pressure or mounting style incorporating the outstanding features of the Hadady

heavy duty hydraulic cylinder.

| Copyright @ 2009-2011 Hadady Machining Co., Inc. 16730 Chicago Avenue Lansing, IL 60438 All Rights Reserved |